This Kyocera FS1020 printer was brought to me because it wasn’t working but the primary fault turned out to be a paper jam.

However the printer had some other problems:

- Light print – Caused by a dirty laser assembly.

- Dark vertical lines – caused by a dirty charge unit corona wire. (The fix is covered in a separate article Kyocera FS-1020 Dark Line In Print – How To Clean A FS1020 Corona Unit)

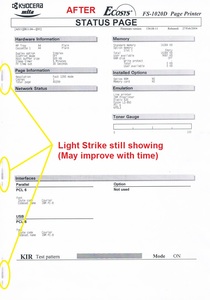

- Light strike – the customer had left the drum unit out of the printer and exposed it to light for too long (can’t be fixed but may improve with time).

In this article I will cover the cleaning procedure for the Laser unit. Note: the procedure for the FS1000, FS1010 and FS1030 are very similar to this.

First off here is a before and after test page showing the faults and how they are improved

It’s possible to clean the laser glass without removing the laser unit from the printer, but to do it properly you need to see what you are cleaning. To get a good clean I like to remove the charge unit from the printer.

As always the first step is to TURN THE PRINTER OFF AND UNPLUG THE POWER CORD!

You will need to remove the 2 screws holding the top cover.

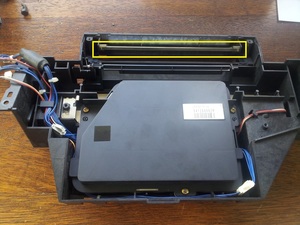

With the top cover removed you will then need to remove both side covers. This is done by popping the clips that hold the side covers on (marked by arrows). For the right side you will also need to remove the memory slot cover by removing the thumb screw at the back of the printer and hinging it to the side. Once the side covers are off, the wires leading from the laser unit to the PCBs on the right hand side can then be disconnected. The 6 screws holding the laser unit can now be removed (marked with yellow circles in the above picture). Note there is one screw on the right side of the printer that isn’t marked.

Remove the 4 screws (marked with yellow circles) to remove the laser unit cover.

The main mirror (marked with the yellow rectangle) can now be inspected and cleaned. The surface you want to clean is the one facing down through the slot in the laser unit casing. NOTE: laser unit mirrors are surface coated and can be scratched or damaged very easily and should only be cleaned with a soft lint free cloth. If required you may also dampen the cloth a little with water. I have never come across a mirror that needed any chemicals or cleaning products to clean.

I removed the mirror from the laser unit to get a better pic of the difference between a dirty and clean laser unit. I don’t recommend you do this as this is a thin piece of glass and can break easily. You may also note the mirror coating is on the top of the glass and not the bottom like any normal mirror, this is done to reduce distortion in the laser.

Once the mirror is clean, all you need to do is reassemble the printer and test.