This is a job I did for a customer’s Oki C3400 that had me scratching my head a bit. It would also affect the Oki C3300 and C3600 model printers as they take the same drum unit.

The following image is a copy of the fault and shows that the main colour affected is cyan (the blue colour) and to a much lesser degree yellow.

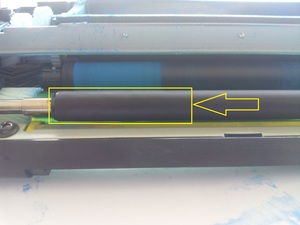

As it turns out the drum unit is to blame. After striping it down for the second time I noticed the charge roller had some slight lumps on the end.

I then removed the charge roller from the drum unit and took the roller off of the chrome steel shaft. It was immediately noticeable that the shaft was the cause of this fault. Rust had built up on the shaft, causing the surface of the roller to become lumpy and cause serious copy quality problems.

From there I simply used some fine wet and dry sand paper to remove the rust and chrome flakes.

With the shaft smooth again I simply slid the charge roller back onto the shaft and fitted it back in the drum unit.

I then cleaned the yellow unit the same way as the cyan.

This fault should only occur in printers that do low volume printing and have the drum units replaced infrequently.

Note: this job is a bit mucky, as to remove the charge roller you will need to take the top off the drum unit/toner hopper, so have some paper or cover sheets to work on.

A easier option for most people will be to purchase a new drum unit for the colour giving the fault

How I can remove the black rubber rcp to steel?

Hi Hugo

The rubber sleeve will slide off with a little effort. I would put one end of the shaft against something solid and push the roller from the other end (note where the roller fits for re-assembly).

Once you get it moving it should slid off quite easily.

Good luck and please let me know how you get on.

I’m just in the middle of stripping one of these printers to try and fix the same problem, the charger roller has noticeable bulges across it. There is rust at the end of the chrome rod and pushing off the roller (which is fun to do) has released a lot of rusty liquid.

Now, having got the rubber off and cleaned the rod up, should the rubber be a “tight” fit to the rod? It fits snugly but can slighty move about.. does that sound about right?

Hi Harvey

It should be tight-ish (it will go on easier than it came off). If you are worried you could try gluing the roller to the shaft. Obviously make sure the glue is well dried before reinstalling the roller.

I don’t remember it being a issue when I did it.